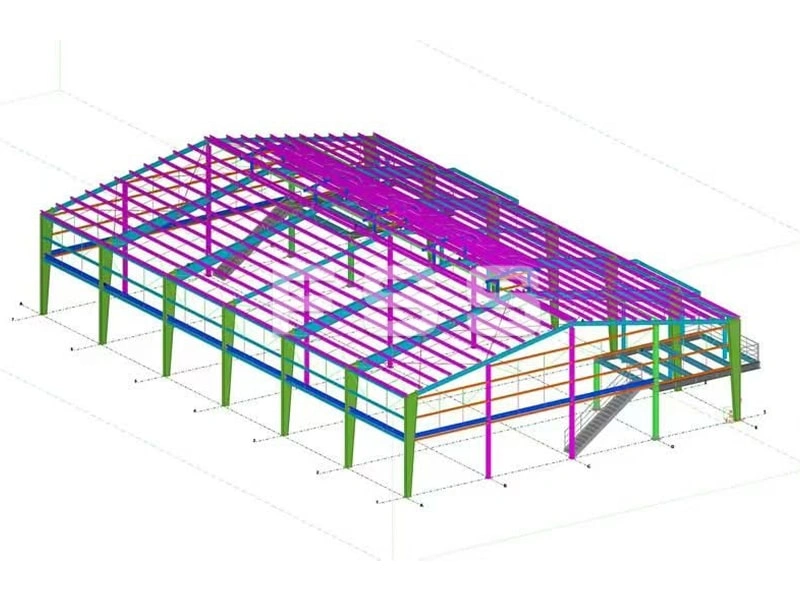

Prefabricated Steel Frames

Industrial-Grade Steel Frame Trusses Solutions for Global Construction

Our prefabricated steel systems are trusted in diverse industries for their precision and scalability:

Heavy-duty steel frame suppliers solutions for factories, power plants, and logistics hubs, with high load-bearing capacity.

Metal structure buildings for airports, metro stations, and bridges, designed for rapid assembly and seismic safety.

Custom prefabricated metal building manufacturers designs for malls, warehouses, and exhibition centers, combining aesthetics and functionality.

Galvanized metal steel frame systems for ports, oil rigs, and coastal shelters, resistant to salt corrosion.

Why choose us?

90% faster installation compared to traditional steel frameworks.

Smart modular designs compatible with BIM/CAD software.

Serving 100+ countries since 2008 as leading steel truss frame suppliers.

| Standard | Protocol | Compliance |

|---|---|---|

| Design Validation | AISC/GB 50017-2017 dual-certified | Third-party SGS/BV structural audits; ANSYS-driven load simulations. |

| Material Inspection | Q355B/Q390B steel batches | Mill test reports (MBR) from Baosteel/Ansteel; chemical composition checks. |

| Production Monitoring | 24/7 AI-powered visual inspection | Automated alarms for weld defects >0.1mm; IoT sensors track torque accuracy (±2%). |

| Final Testing | Salt spray test (ISO 9227) | 2,000+ hours corrosion resistance; fire-retardant coatings (EN 13501-1). |

| Certifications | ISO 9001, CE, OHSAS 18001 | Green building compliance (LEED/WELL standards). |

Design & Engineering

Our design team uses BIM modeling and finite element analysis to optimize stress distribution and ensure compliance with AISC/GB 50017-2017 standards. Leveraging ANSYS simulations, we eliminate clashes and enhance structural efficiency. Backed by 30+ engineers with ASCE/ICE certifications and 10+ years of experience, every prefabricated metal building manufacturers project is tailored for durability and precision.

Material Preparation

High-strength Q355B/Q390B steel is cut using laser technology with ±0.5mm precision. Advanced auto-punch marking ensures accurate hole alignment, while blockchain-enabled traceability tracks material batches from suppliers like Baosteel.

Robotic Welding

Automated MIG/TIG welding robots deliver full penetration welds, achieving 100% penetration rates. Phased-array ultrasonic testing (UT 20dB SNR) inspects weld quality in real time, eliminating human error.

Modular Assembly

Pre-assembled in 12m spans, components feature bolted/brazed joints with anti-vibration dampers. Each joint undergoes torque control (±2% accuracy) to guarantee stability during transportation and on-site integration.

Quality Inspection

Coordinate-measuring machines (CMM) validate dimensional accuracy within ±0.3mm. Hydraulic load tests simulate up to 2x design capacity, while salt spray tests (ISO 9227) certify 2,000+ hours of corrosion resistance.

Climate-Controlled Packaging

Components are sealed in vacuum crates with VCI corrosion inhibitors and GPS tags for real-time tracking. This ensures minimal moisture damage during global shipments.

Smart Packaging: Vacuum-sealed prefabricated metal building manufacturers components prevent moisture damage.

Global Logistics: Partnered with Maersk/COSCO for heavy-lift shipments; SPMT trailers handle 800-ton loads.

Real-Time Tracking: IoT sensors monitor humidity/temperature; blockchain-enabled customs docs reduce delays.

On-Site Support: 24/7 multilingual engineers assist assembly in 45+ countries.

15+ Years Leadership: Specialized in prefabricated steel since 2008, serving Fortune 500 clients and governments.

Military-Grade Precision: Q355B steel with HDG 850g/m² galvanization for 50-year durability.

End-to-End Services: From design to assembly, backed by 12 global warehouses.

*Required fields